Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Published:January 2, 2021, Category: Ideas / Technology

Overview

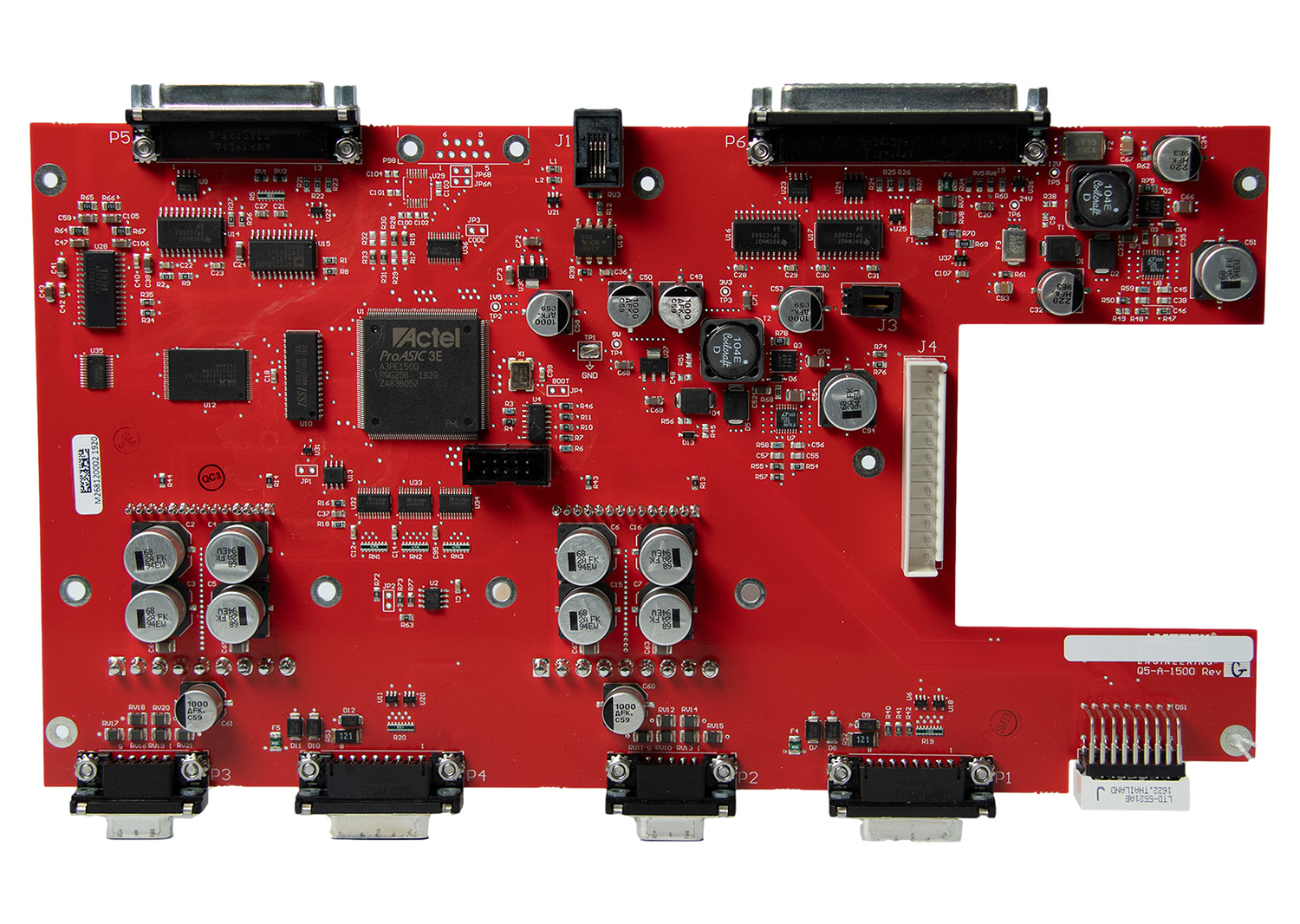

A leading oilfield equipment provider partnered with us to develop a rugged and reliable Motor Control Board for use in remote and harsh oilfield environments. The board was required to control high-torque electric motors used in downhole and surface applications, including pumps, compressors, and valve actuators.

Objectives

Design Challenges

Key Design Features

Manufacturing Highlights

Results

Conclusion

This project demonstrated our capability to deliver mission-critical control electronics for the oil and gas industry. Our engineering and manufacturing teams ensured the Motor Control Board met stringent safety, reliability, and performance requirements in a highly demanding application.