Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Oil And Gas

- Home

- Oil And Gas

Turnkey Electronics Assembly Services for the Oil and Gas Industry

Electronic devices are everywhere in oil and gas sites. They power drilling machines, control safety systems, and monitor equipment. Sensors gather data about temperature, pressure, and flow, helping operators make quick decisions. As automation grows, electronics become even more important, helping jobs get done faster and safer.

// Expertise from Concept to Completion

Ensuring Compliance with Industry-Specific Standards for Electronics Assembly in the Oil and Gas

We understand that the oil and gas industry requires tailored solutions that can withstand extreme temperatures, pressure variations, and corrosive elements. Our electronics assembly services encompass the complete process of design, prototyping, and manufacturing of electronic components suited for various applications, including drilling, exploration, refining, and transportation. Our engineers work closely with clients to develop products that meet specific industry standards and performance criteria, ensuring compliance and reliability.

// Services Scope

Some Of Our Electronics Assembly Services For Oil And Gas Industry:

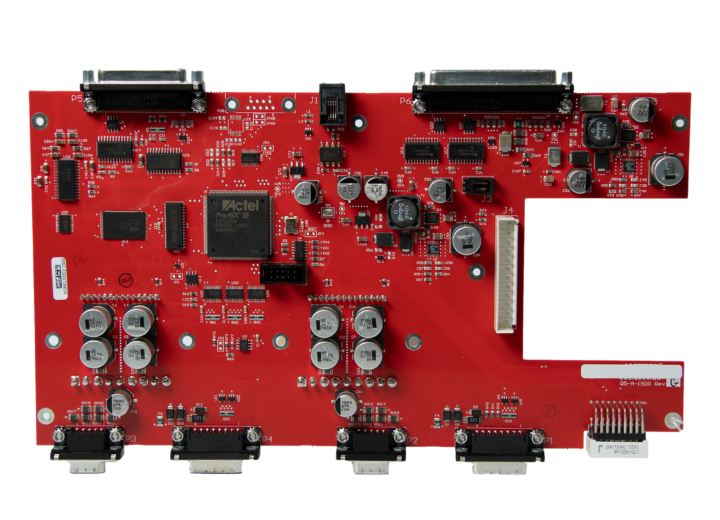

Through-Hole and Surface Mount Assembly

The oil and gas industry relies on our expert services to choose between THT and SMT, tailored to specific applications, environmental conditions, and production requirements. We provide THT solutions ideal for rugged equipment, SMT for compact, high-volume applications, and hybrid approaches that balance THT's robustness with SMT's efficiency.

Conformal Coating & Encapsulation

Whether it’s acrylic, silicone, urethane, or epoxy-based coatings, we apply materials that match the specific environmental and operational demands of your application. We offer both selective coating and full encapsulation (potting) services, including automated and manual processes for optimal precision and coverage.

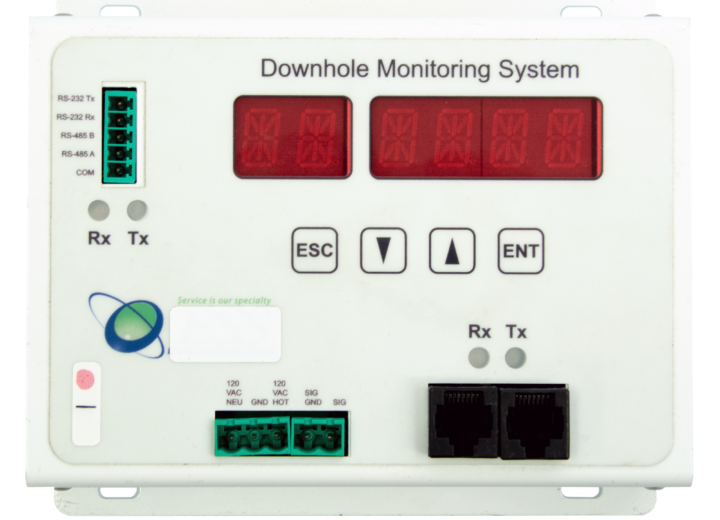

Box Build & System Integration

Our end-to-end capabilities include mechanical assembly, cable and wire harness integration, PCB installation, firmware loading, full system testing, and final packaging.

Our services include:

- Custom enclosure assembly (NEMA/IP rated)

- Cable routing and harnessing

- Power distribution integration

- PCB installation and system-level interconnect

- Firmware installation and configuration

- Functional and environmental testing

- Final system validation and documentation

Testing & Quality Assurance

Our capabilities ensure that every product meets stringent performance, safety, and reliability standards required for operation in harsh and mission-critical environments.

Our services include:

- Functional Testing: Validating full system operation under simulated field conditions.

- In-Circuit Testing (ICT): Verifying component placement, orientation, and performance.

- Environmental Stress Screening (ESS): Identifying early-life failures with thermal cycling and vibration testing.

- Burn-In Testing: Ensuring durability and stability under prolonged electrical load.

- Conformity to Industry Standards: Compliance with IPC, ISO, and relevant oil and gas certifications.

// Portfolio

Our Electronic Assemblies For Gas & Oil Industry

// Most Frequent Questions

Electronic Assemblies For Gas & Oil Industry FAQ

Electronics in the oil and gas industry must withstand extreme conditions, including:

- High temperatures (up to 200°C in some cases).

- High pressures (up to 25 kpsi).

- Harsh environments like saltwater, vibrations, dirt, and explosive atmospheres.

- Flammable gases, requiring intrinsically safe and explosion-proof designs. To address these, assemblies often use robust materials, conformal coatings, and comply with standards like ATEX and IECEx for explosive environments.

Electronics assemblies must comply with industry standards such as:

- IPC-A-610: Ensures high-quality workmanship for electronic assemblies.

- IPC/WHMA-A-620: Covers cable and wire harness assemblies.

- ATEX Directive 2014/34/EU and EN ISO/IEC 80079-34:2018: Ensures equipment is safe for use in explosive atmospheres.

- RoHS compliance: Ensures environmentally responsible manufacturing by restricting hazardous substances. These standards guarantee reliability, safety, and performance in demanding conditions.

Common assemblies include:

- Printed Circuit Board (PCB) Assemblies: Used in sensors, flow meters, and control systems for monitoring and data processing.

- Cable and Wire Harnesses: Provide reliable electrical connections in drilling equipment and rigs.

- Box Builds: Complete electronic systems integrating PCBs, wiring, and enclosures for rugged environments.

- Energy Chains: Protect cables in moving machinery like pipe-handling devices and top drives. These assemblies are designed for durability, precision, and compliance with safety regulations.

Reliability is paramount because:

- Downtime in oil and gas operations is costly, with even short interruptions leading to significant financial losses.

- Equipment failures in remote or offshore locations can be difficult and expensive to repair.

- Safety risks from flammable gases or high-pressure environments require fail-safe systems. EMS providers use rigorous testing protocols like burn-in testing and environmental stress screening to ensure components perform under extreme conditions.

Protection methods include:

- Conformal Coatings: Shield against moisture, dust, and corrosion.

- Potted Assemblies: Encapsulate electronics for added protection against vibrations and pressure.

- High-Grade Materials: Use of RoHS-compliant, lead-free components to withstand high temperatures and pressures.

- Rugged Enclosures: Explosion-proof and flameproof designs for safety in volatile environments.

These components are critical for instrumentation:

- Sensors: Provide continuous measurements to detect gas emissions, pressure, temperature, or flow.

- Transducers: Convert physical variables (e.g., pressure, temperature) into electrical signals.

- Transmitters: Relay these signals to control systems for monitoring and decision-making. They ensure operational safety, environmental compliance, and efficient resource extraction.

Key techniques include:

- Surface Mount Technology (SMT): For high-density, compact, and efficient PCB assemblies.

- Through-Hole Technology (THT): For durable connections in high-vibration environments.

- Automated Optical Inspection (AOI): Ensures quality and precision in PCB manufacturing.

- Thermal Profiling: Optimizes thermal management for reliable performance in extreme temperatures.

Rapid prototyping allows EMS providers to:

- Quickly develop and test custom solutions for specific oil and gas applications.

- Reduce time to market by turning concepts into working models efficiently.

- Ensure compatibility with existing systems and compliance with industry standards. This is critical for meeting the unique demands of diverse oil and gas projects.

- Expertise: Access to specialized knowledge in designing rugged, reliable electronics.

- Cost Efficiency: Turnkey services reduce in-house manufacturing costs.

- Quality Assurance: Compliance with industry standards and rigorous testing.

- Flexibility: Custom solutions tailored to specific operational needs.

- Reliable Supply Chains: Streamlined procurement for remote or offshore projects.

QUALITY & EXPERIENCE

Our technicians have built their skills over decades of hands-on work, always meeting the highest industry standards.

TIME DELIVERY

We do our best to deliver on time, even if it means sending partial shipments. This way, you can keep up with your production flow without delay.

COST EFFECTIVE

We check every project and agree on the price and schedule before starting. For big projects, we can usually make an affordable repair/rework plan.

// Start to Finish Electronics Manufacturing Services

EMS' Capabilities

EMS stands out in turning ideas into finished products in one location. For more than 19 years, we have assisted entrepreneurs in turning ideas into finished products. We also excel at handling “Dirty Jobs” – the demanding, labor-intensive tasks that can hinder production. Whether it’s a medical device, military equipment, or a high-end gadget, we have the tools and experience to realize your vision.

GETTING STARTED

Getting your project started is easy. Just share your idea with our team, and we will give you expert advice and suggestions on the materials, timeline, and cost breakdown required to complete the project. We guarantee the highest level of performance and effectiveness for your particular use.