Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Box Build Electro-Mechanical Assembly

- Home

- Box Build Electro-Mechanical Assembly

Box Build Electro-Mechanical Assembly Services

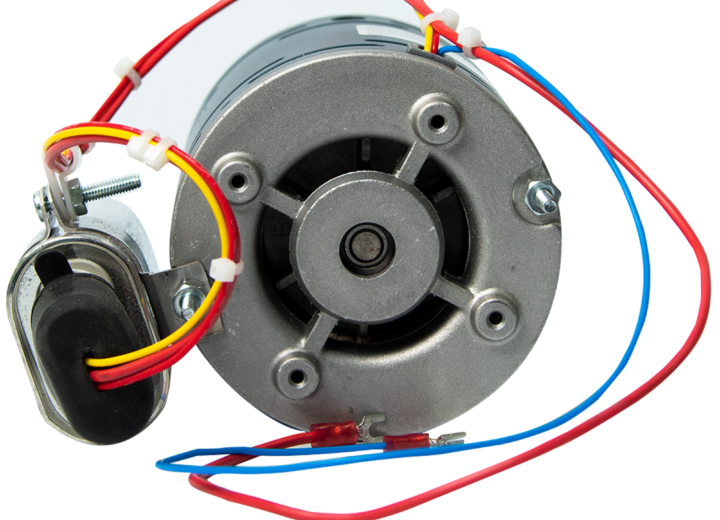

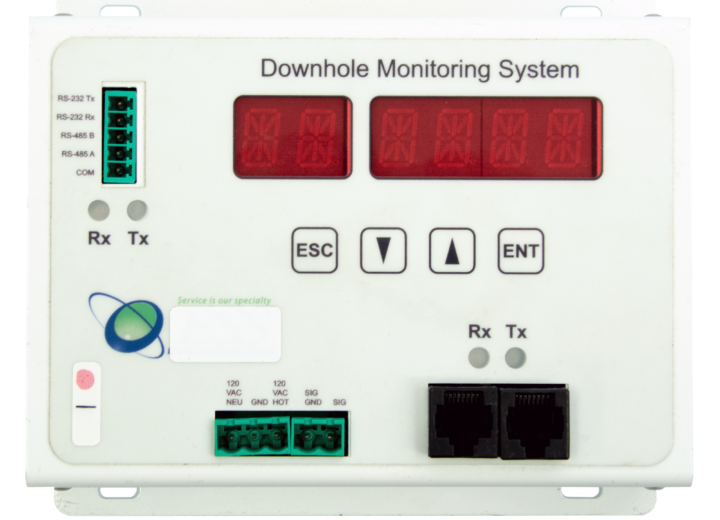

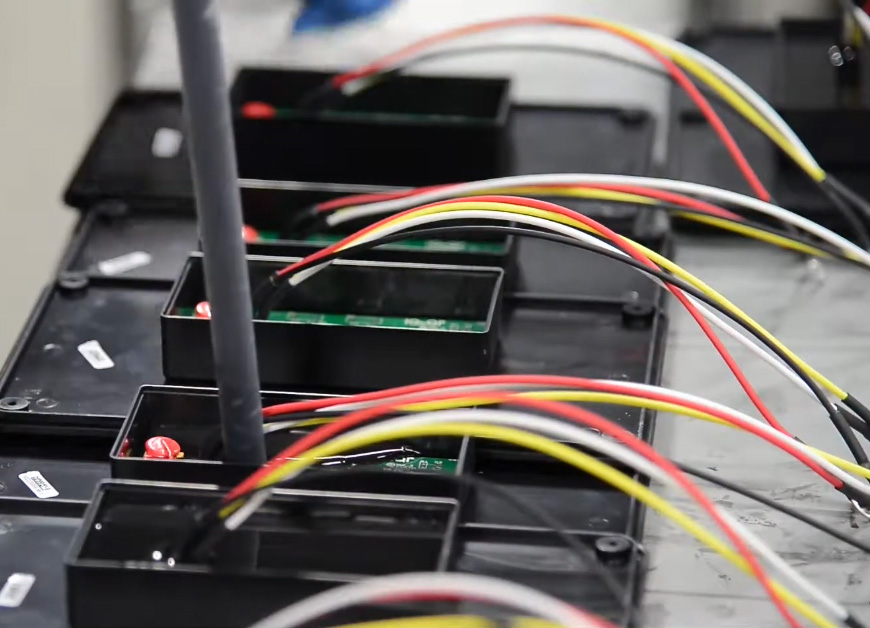

Box build electro-mechanical assembly refers to the comprehensive assembly of electronic components within a defined enclosure, commonly known as a box. This process can encompass a range of activities from mounting circuit boards and attaching connectors to integrating various electro-mechanical components, such as switches, displays, and power supplies. The ultimate goal is to create a cohesive unit that meets both performance standards and design specifications.

// ELECTRICAL AND ELECTRO-MECHANICAL ASSEMBLY

Minimize Supply Chain Risk With EMS' Integrated Box Build Assembly Services

EMS designs, builds, and maintains a wide variety of box build electronic assemblies for customers across many industries. From initial design and prototyping to large-scale manufacturing, our engineering and production teams are ready to help with your electro-mechanical projects. With years of experience, we ensure that your project moves smoothly from start to finish.

We can build and assemble your entire product so it’s ready to use when it leaves our workshop. We handle the mechanical parts, assemble the board, connect the electrical components, and make use of our in-house wiring harness skills to cut down your assembly time. Having one source for everything makes the process simpler, quicker, and more affordable. It also means you have only one point of accountability for the entire project.

// Services Scope

Our Box Build Assembly Capabilities

Component Sourcing

Our extensive network of providers will supply every component. Among these are power supplies, relays, DIN rails, sensors, and switches. In addition to all the components required to finish your box build, we can supply enclosures of any size and material.

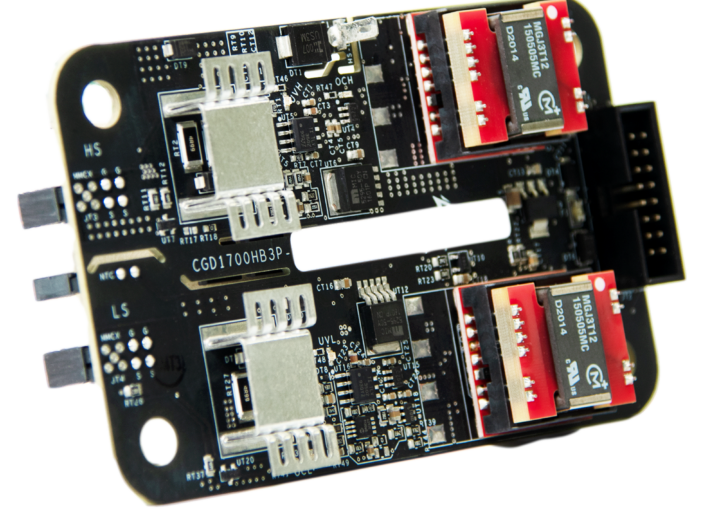

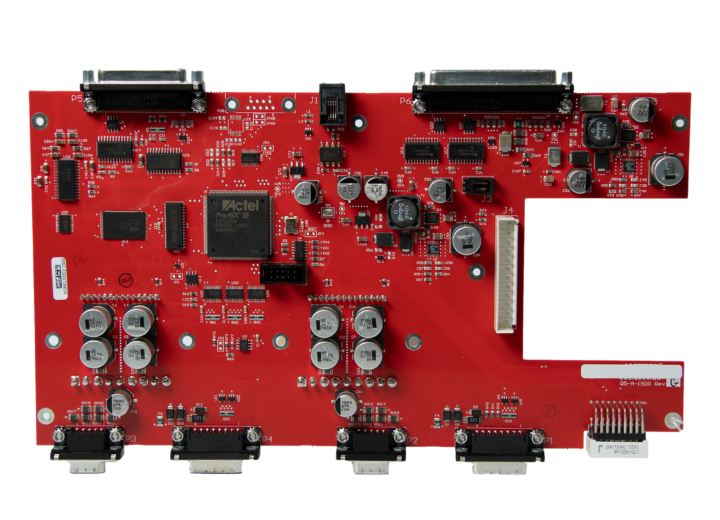

PCB Design & Assembly

Our comprehensive PCBA services encompass every phase of the process, from design through to assembly including rigorous testing. We utilize state-of-the-art SMT to deliver compact, high-density PCB assemblies as well as THT and mixed technologies.

Cable & Wire Assembly

We are fully equipped to handle all challenges related to creating cable and wire interconnections between the board and electronic elements like sensors, displays, ventilation, or power supplies within an enclosure, including complex wire and harness connections.

Sub-Assemblies

We carefully assemble components like control panels, PDUs, communication modules, and sensor arrays. Our goal is to prepare everything so it can connect smoothly with the overall system during the final assembly.

System Level Assembly

Our system-level assembly focuses on ensuring every part of the product work together perfectly to achieve seamless operations and optimal performance. Our goal is to meet strict quality and dependability standards.

Software Installation & Configuration

We provide software loading and configuration as part of the box build competencies, providing a solution that is ready for deployment.

Box Build Assembly Testing

Quality assurance is crucial in electro-mechanical assembly, requiring multiple tests including functional, performance, and environmental testing to ensure the product functions correctly under expected conditions, ensuring optimal performance.

Packaging, Labeling, Shipping

Before starting production, we work with you to plan the packaging, labeling, and delivery of the product. This step makes sure everything is secure during shipping and that your product arrives in perfect shape and working order.

Warehousing

You can count on us for a variety of custom-sized packaging to keep your components safe during storage and shipping. Our solutions protect assembled parts from damage throughout the warehouse stay and along the supply chain.

// Most Frequent Questions

Box Build Electro-Mechanical Assembly FAQ

A box build assembly, also known as systems integration, involves assembling electronic components, such as printed circuit boards (PCBs), wiring, connectors, and enclosures, into a complete, functional product. It includes everything from design to testing, packaging, and shipping, tailored to specific requirements.

PCB assembly focuses on mounting and soldering components onto a circuit board. Box build is a broader process, integrating the PCBA with other components (cables, enclosures, etc.) to create a complete, functional system. PCB assembly is often a subset of box build.

- PCBs: The core electronic platform.

- Enclosures: Protective casings (metal or plastic).

- Wire Harnesses/Cables: For electrical connectivity.

- Electromechanical Parts: Switches, sensors, or displays.

- Power Supplies: For regulating voltage. The complexity varies from simple PCB enclosures to intricate systems with multiple sub-assemblies.

- Bill of Materials (BOM): List of components, part numbers, and quantities.

- Assembly Drawings: Visual instructions, from simple diagrams to 3D CAD models.

- Regulatory Requirements: Standards like RoHS, UL, or FCC.

- Test Procedures: Specifications for functional and safety tests.

- Packaging/Shipping Needs: Details on size, weight, and handling.

Yes, box builds are highly customizable, from enclosure design to component selection, ensuring compatibility with your systems and aesthetic preferences.

Common industries include electronics, aerospace, automotive, medical, telecommunications, and industrial applications for products like control panels, diagnostic devices, and battery systems.

Lead times vary based on complexity and component availability, typically ranging from 2-4 weeks after receiving all components. Prototypes may take less time, while high-volume orders could take longer.

// Product Portfolio

Recent Engineering Projects

// Start to Finish Electronics Manufacturing Services

EMS' Capabilities

EMS stands out in turning ideas into finished products in one location. For more than 19 years, we have assisted entrepreneurs in turning ideas into finished products. We also excel at handling “Dirty Jobs” – the demanding, labor-intensive tasks that can hinder production. Whether it’s a medical device, military equipment, or a high-end gadget, we have the tools and experience to realize your vision.

GETTING STARTED

Getting your project started is easy. Just share your idea with our team, and we will give you expert advice and suggestions on the materials, timeline, and cost breakdown required to complete the project. We guarantee the highest level of performance and effectiveness for your particular use.