Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Case Study: Design and Manufacturing of a Downhole Monitoring System for the Oil and Gas Industry

Published: January 10, 2020, Category: Design / Development

Overview

A leading oilfield services company aimed to develop a next-generation downhole monitoring system to enhance real-time data acquisition for optimizing oil and gas production. The system needed to monitor critical parameters such as pressure, temperature, and vibration in harsh downhole environments, characterized by high temperatures (up to 175°C), high pressures (up to 10,000 psi), and significant vibration. The goal was to create a reliable, cost-effective, and durable system to reduce operational downtime, improve production efficiency, and support sustainable resource extraction.

Objective

To design and manufacture a downhole monitoring system capable of:

- Providing real-time data on pressure, temperature, and vibration.

- Operating reliably in extreme downhole conditions.

- Integrating with existing well infrastructure and surface control systems.

- Minimizing production costs and lead times while maintaining high quality.

Design and Engineering Challenges

- Environmental Extremes: Component selection had to ensure operation at HT/HP (High Temperature/High Pressure) conditions.

- Form Factor: The tool had to fit within narrow boreholes (~2.875 inches OD).

- Signal Integrity: Long-distance telemetry under EMI conditions.

- Power Efficiency: Operate reliably on limited battery supply for extended deployments (30–90 days).

Solution Architecture

1. Sensor Suite Design

- Pressure Sensor: Quartz resonator type for high-accuracy pressure readings.

- Temperature Sensor: Platinum RTD (Resistance Temperature Detector).

- Accelerometers: MEMS-based, tri-axial for shock and vibration analysis.

- All sensors encapsulated in a hermetically sealed stainless steel chamber with sapphire window.

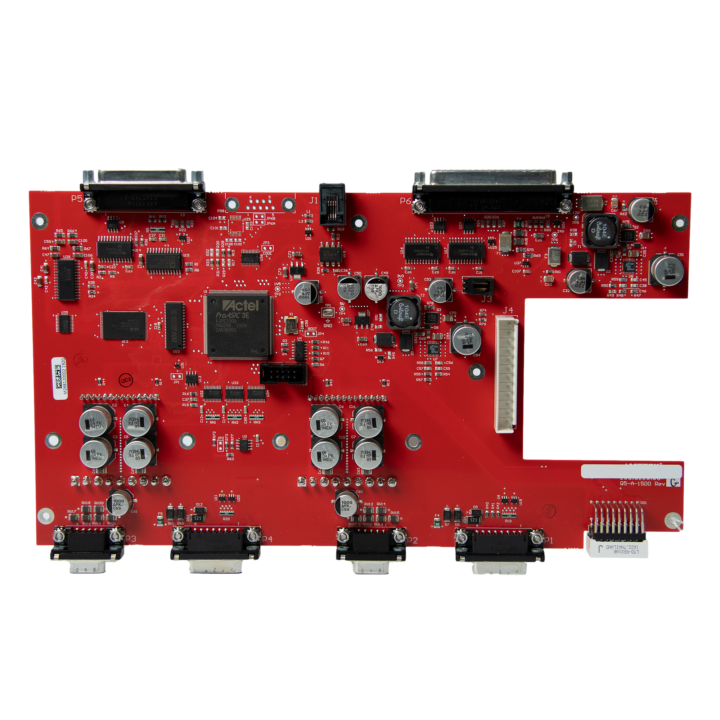

2. Electronics and PCB Design

- Multi-layer high-temperature PCB using polyimide material.

- Use of downhole-rated components (e.g., HT-rated op-amps, microcontrollers).

- Redundant signal pathways and watchdog circuits for fault tolerance.

- Designed for minimal drift over extended exposure to high temperature.

3. Power System

- Custom battery pack using Lithium Thionyl Chloride (Li-SOCl₂) cells with thermal shielding.

- Ultra-low-power microcontroller firmware to reduce active cycles.

- Onboard real-time clock with sleep-wake scheduling.

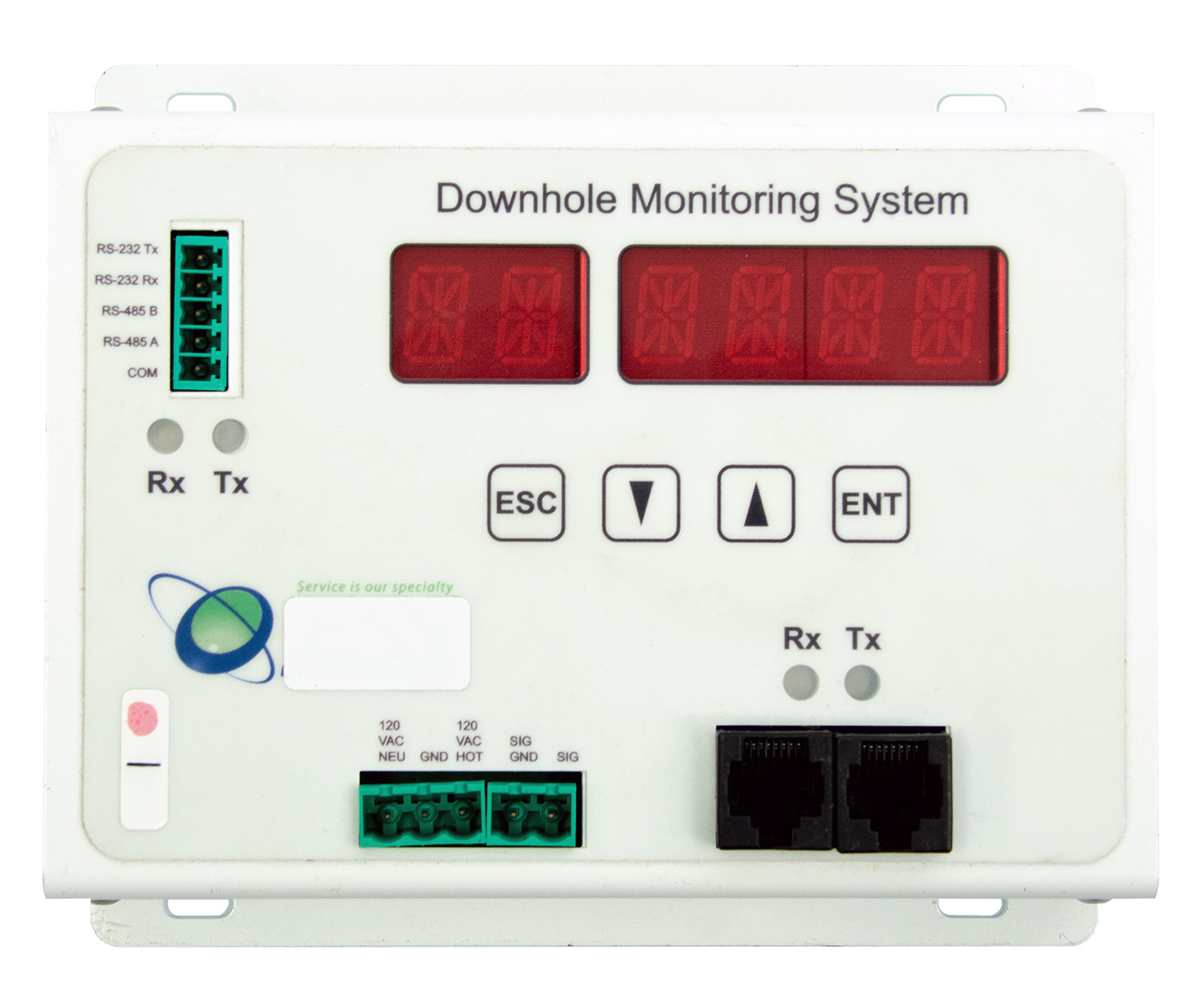

4. Data Handling & Communication

- Local Data Logging: High-capacity flash memory with cyclic redundancy checks.

- Telemetry: Inductive coupling for wireless communication during retrieval, or optional fiber-optic link.

- Surface decoding software developed in Python with real-time visualization dashboard.

Manufacturing Approach

1. Materials & Assembly

- Use of Inconel 718 for housing due to corrosion resistance and high strength.

- Laser welding and helium leak testing for hermetic seals.

- Conformal coating and potting for vibration and moisture protection.

2. Testing & Validation

- Environmental simulation: thermal cycling, pressure chamber testing up to 35,000 psi.

- Shock and vibration testing per API RP 10F standards.

- Functional validation under simulated well conditions.

Project Outcome

- Deployment-ready system delivered in 14 months.

- Successfully deployed in deepwater Gulf of Mexico and North Sea operations.

- Achieved 99.2% uptime over multiple 60-day deployments.

- Helped operators reduce unplanned downtime by 17% and improve reservoir analytics.

Key Takeaways

- Cross-discipline integration (electronics, materials, mechanical) was essential.

- Early simulation and prototyping reduced failure risk in field trials.

- Use of ruggedized, application-specific components ensured performance under extreme conditions.